사업소개

미래지향적인 기술력으로 끊임없이 도전하는 기업

단결정 장비 사업부 (EPICA)

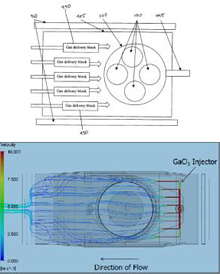

EPICA- Advanced HVPE System

Technology Introduction

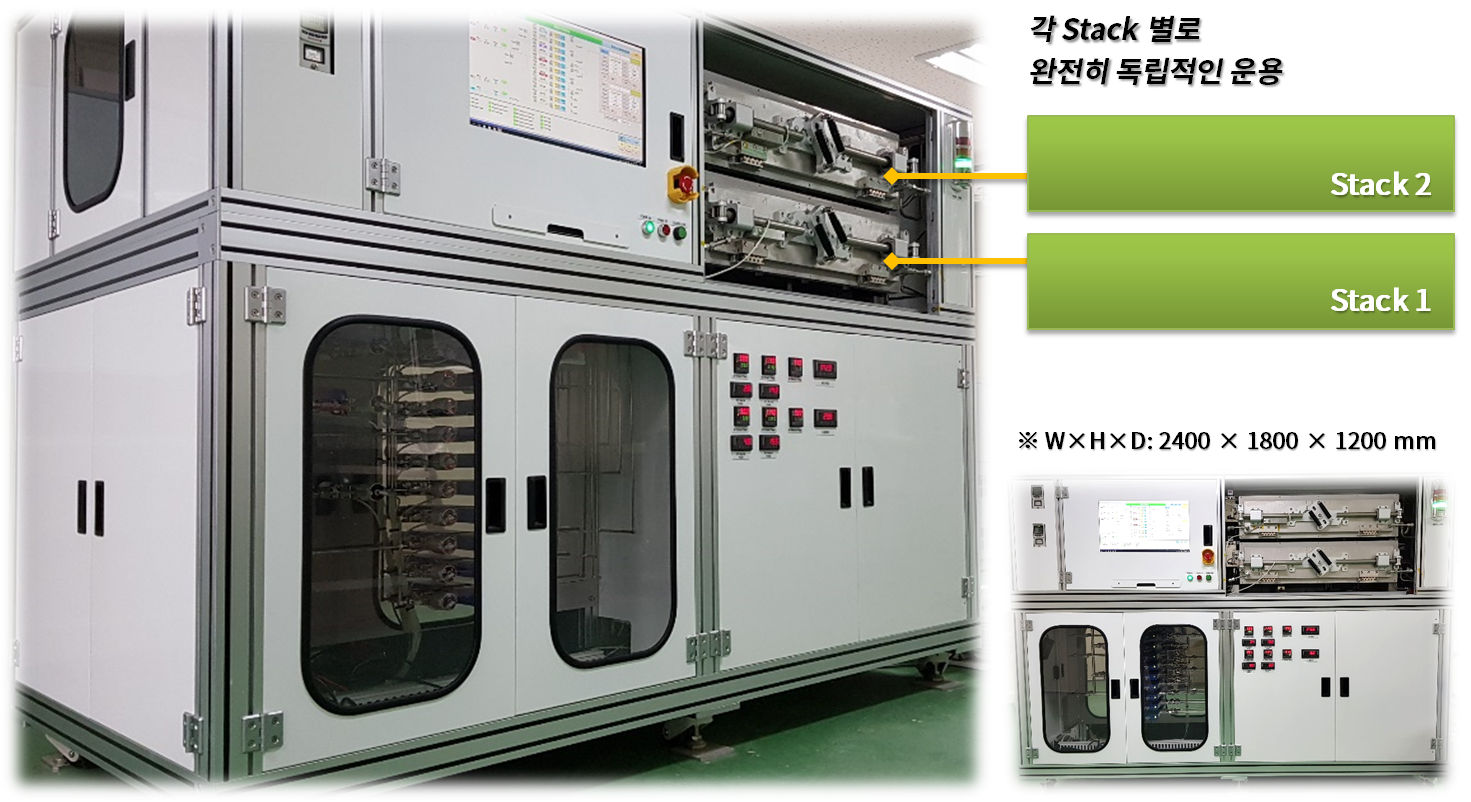

EPICA – GaN Template Mass Production System

EPICA – 2 Stack System

Comparison of Conventional HVPEs and EPICA

| 구분 | Conventional HVPE | CVD Based HVPE | EPICA HVPE |

|---|---|---|---|

| 장비의 기본 형태 |

Horizontal or Vertical Type |

|

Multi-Stacked Extendable |

| 특징 |

|

|

|

| 용량 | ≤ 4 inch × 3ea / ≤ 6 inch × 1ea | 4 inch × 9ea / 6 inch × 4ea | 4 inch × 6ea / 6 inch × 3ea (@ One Unit Reactor) |

| 최대 성장률 | ≤ 150 ㎛/h (Horizontal) ≤ 300 ㎛/h (Vertical) |

≤ 30 ㎛/h | ≤ 120 ㎛/h |

| 20 ㎛ target 표준 공정 시간 |

≥ 150 min (지속적인 Heater 가동 및 Cleaning 공정 포함) |

≤ 180 min (추정) | ≤ 200 min (Reactor 승온, 냉각 시간 포함) |

| H2 gas 사용 및 압력 control |

Not available (or Dangerous) | Available (추정) | Available |

| System 운용 비용 | Relatively Mid. cost | Relatively High cost (from Initial Process) |

Relatively Low cost |

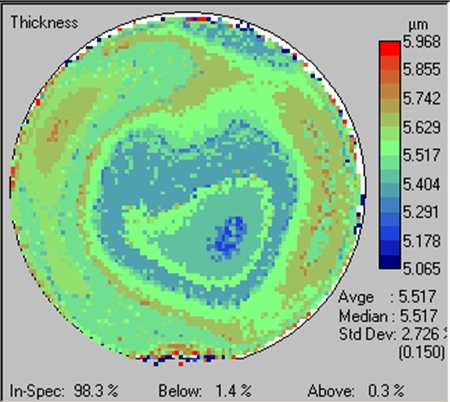

Performance - GaN on 4 inch NSS

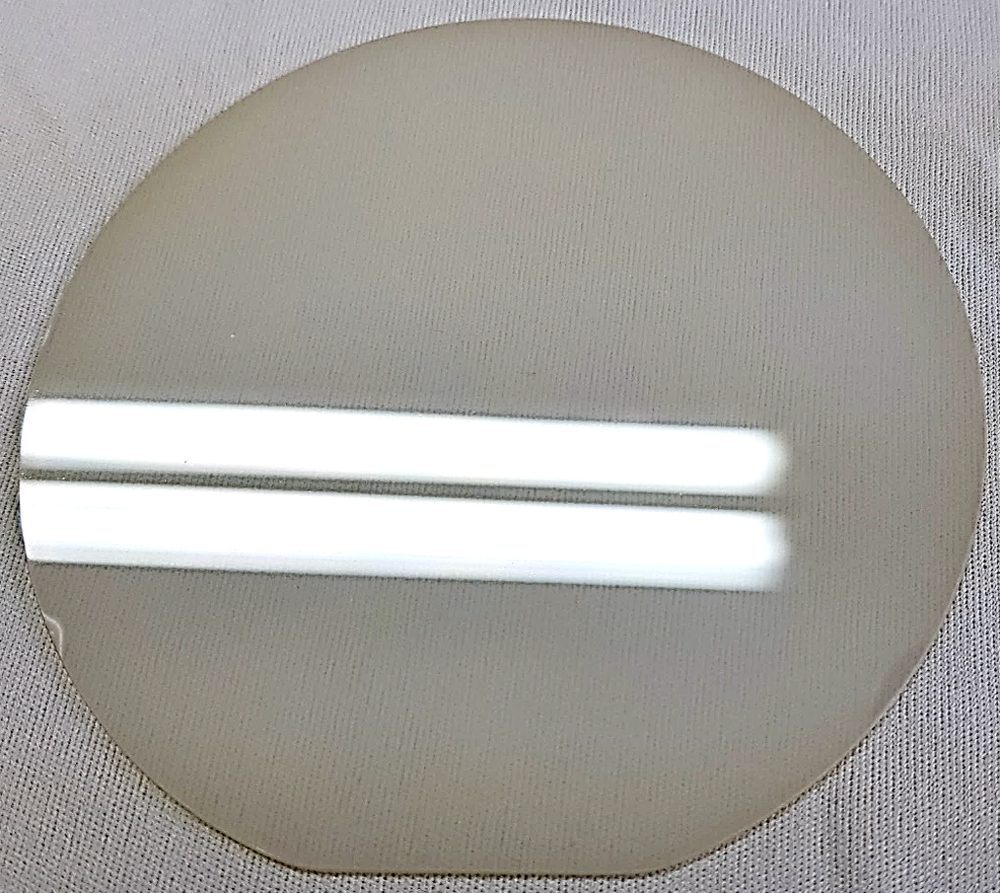

NSS

Thickness STD: 2.72 % @ 5.51 ㎛

XRC ω-scan

(002) 309.6 arcsec

(102) 370.8 arcsec

Under developing for high quality

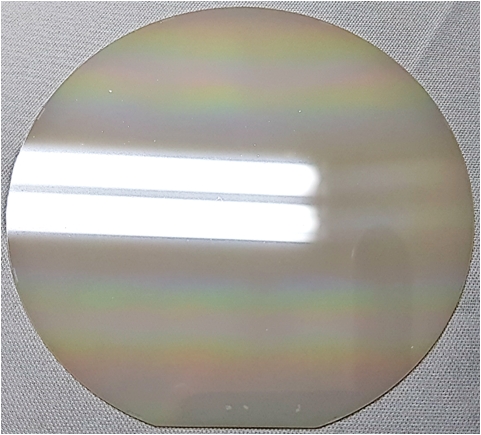

Performance – GaN on 4 inch AlN Sputtered PSS

PSS Cone: 1.75 × 2.75 ㎛

AlN 30 nm By Sputter

GaN Thickness: 4.82 ㎛

XRC ω-scan

(002) 158.4 arcsec

(102) 219.6 arcsec

Under developing for high quality

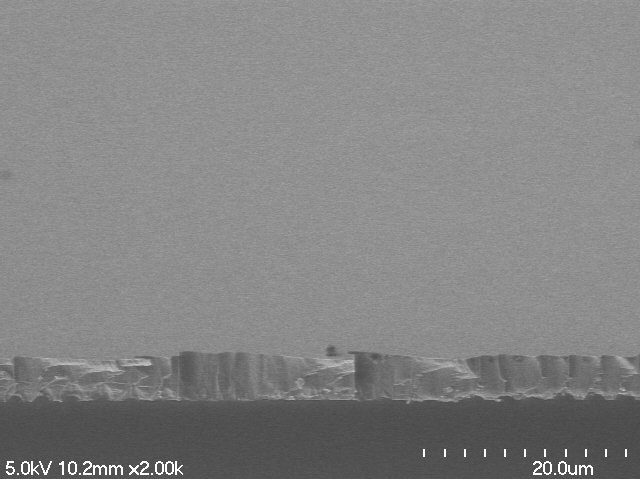

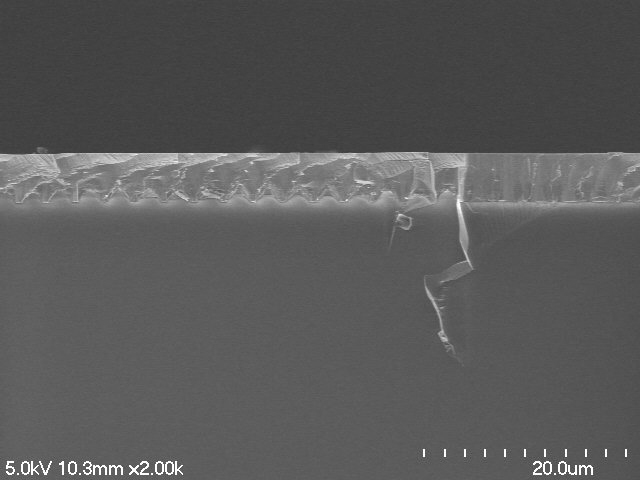

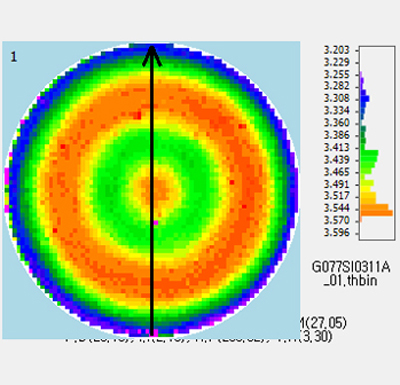

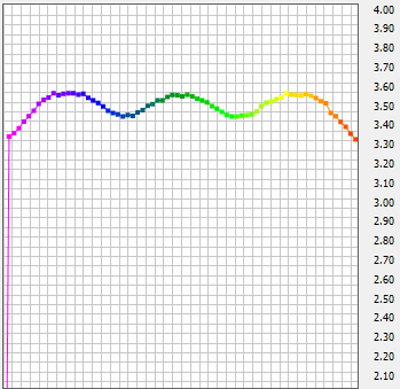

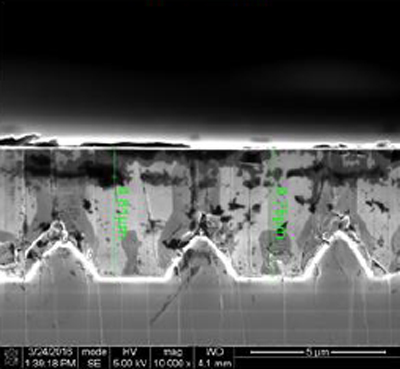

Performance – GaN on 6 inch AlN Sputtered PSS

XRC ω-scan

(002) 179 arcsec

(102) 268 arcsec

Thickness STD: 2.32 % @ 3.45 ㎛

Cross-section

System Specification Chart

| Division | Item | Unit | Specification | |

|---|---|---|---|---|

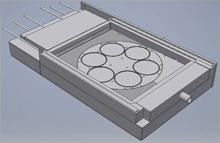

| Hardware | Reactor Type | - | Multi-Stacked Structure of Unit Reactor (SUS Chamber) | |

| Dimension | [mm] | About < 900 × < 700 × < 200 (Unit Reactor) | ||

| Capacity | 2 inch [ea] | 21 / Reactor | The number of Reactors (stack) is determined by the customer’s requirements. | |

| 4 inch [ea] | 6 / Reactor | |||

| 6 inch [ea] | 3 / Reactor | |||

| Process Run time | [min] | ~ 210 (Manual loading, ~ 10 ㎛ target) | ||

| Max. Temperature | [℃] | 1,150 (@ Heater Zone) | ||

| Temp. Ramping rate | [℃/min] | ~ 50 (≤ 800 ℃ Heating), ~ 10 (Avg. Cooling) | ||

| Rotation speed | [RPM] | About 15 | ||

| Process | Growth rate | [㎛/hr] | 2 ~ 120 | |

| WIW, WTW thickness STD | % | ≤ 2 | ||

| WIW, WTW sheet resistance STD | % | ≤ 2 | ||

| Doping range | [ N / ㎤] | 5 × 1017 ~ 2 × 1019 | ||

| H2 carrier Gas | Option | Available (by the customer’s requirements) | ||

| Reactor Pressure Control | Option | Available (by the customer’s requirements) | ||

Intellectual Properties

| No. | 발명 명칭 | 국적 | 출원번호 | 등록여부 | 등록번호 |

|---|---|---|---|---|---|

| 1 | 웨이퍼 회전 장치 | 대한민국 | 10-2017-0036204 | 등록 | 10-1885026 |

| 2 | 화학기상증착용반응기 및 이를 포함하는 화학기상증착장치 | 대한민국 | 10-2017-0047089 | 등록 | 10-2008056 |

| 3 | 웨이퍼 회전 장치 | PCT | PCT/KR2018/002773 | 출원 완료 | - |

| 4 | 화학기상증착용반응기 및 이를 포함하는 화학기상증착장치 | PCT | PCT/KR2018/002774 | 출원 완료 | - |