BUSINESS

A Company that Constantly Challenges with

Future-oriented Technology

CERAMIC Division

1. Nextrema Glass Ceramic

Nextrema is a glass ceramic designed and designed for extreme conditions with a sleek appearance such as glass and excellent thermal, chemical and optical properties.

Properties of material

- High heat resistance - Heat resistance up to 950°C depending on type

- (N)High durability - glass ceramic with nearly zero thermal expansion characteristics even under demanding conditions and extreme conditions

- High thermal shock resistance up to 820°C

- Different levels of protection and filter performance depending on the material type and material thickness of the wide transmittance spectrum at the entire wavelength of visible light and IR range.

- High mechanical immunity - no additional reinforcement process required

- Chemical resistance - resistant to acids (DIN 12116), bases (ISO 695) and hydrolysis effects (DIN ISO 719).

- Process inert - no unnecessary interaction depending on the characteristics of the glass ceramic and the environment, for use in extreme processes (e.g. coating processes)

- Uniform color material - does not cloud, yellowish or bleached over time during normal use

Major application field

- Carrier plates and process materials in semiconductor and display production processes, covers or filters using inner lining or heat shield heat radiation in hot industrial chambers, or IR drying equipment, disinfection equipment, covers of indoor and outdoor heaters, anti-glaze covers for infrared heaters, architecture, furniture and appliances.

Product Type

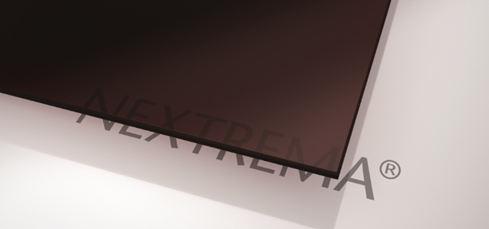

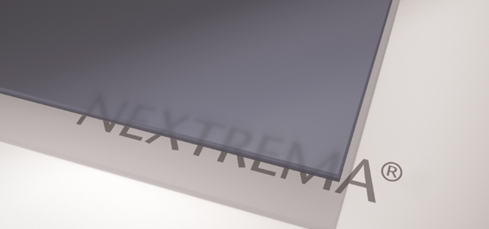

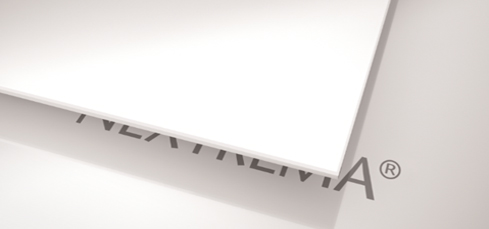

NEXTREMA® Tint (712-3)

NEXTREMA® Transparent Blue Gray (712-6)

NEXTREMA® Opaque Gray (712-8)

NEXTREMA® Translucent White (724-5)

NEXTREMA®Transparent (724-3)

NEXTREMA® Opaque White (724-8)

2. Zerodur Glass Ceramic

The extremely low thermal expansion glass ceramic Zerodur is an inorganic, non-porous lithium aluminum oxide silicon oxide glass ceramic characterized by nanocrystals evenly distributed within residual glass.

High precision in fine-grained, state-of-the-art applications, making glass ceramics suitable for IC (Interated Circuit) and FPD (Flat Panel Display) lithography, high-precision metering and astronomy, where geometric shapes and distance changes should be minimized as much as possible.

Properties of material

- Very low thermal expansion coefficient (CTE-thermal expansion coefficient) for a wide range of overall volumetric temperatures.

- Superior CTE homogeneity across volumes

- Very low levels of nesting, streaking, and internal stress

- Wide range of accurate geometric shapes

- Polishing with very smooth surface roughness below 1 nm RMS

- Excellent chemical stability

- Reliable properties for small parts and large mirror substrates

* Mean coefficient of linear thermal expansion

| CTE Grades | CTE (0°C; 50°C)* |

|---|---|

| ZERODUR® Expansion Class 2 | 0 ± 0.100 ppm/K |

| ZERODUR® Expansion Class 1 | 0 ± 0.050 ppm/K |

| ZERODUR® Expansion Class 0 | 0 ± 0.020 ppm/K |

| ZERODUR® Expansion Class 0 SPECIAL | 0 ± 0.010 ppm/K |

| ZERODUR® Expansion Class 0 EXTREME | 0 ± 0.007 ppm/K |

| ZERODUR® TAILORED | Tailored ± 0.020 ppm/K (± 0.010 ppm/K upon request) Optimized for application temperature profile |

* CTE (0°C; 50°C) represents the average coefficient of linear thermal expansion in the temperature range.

Major application field

- Mirror board material for solar observation, serves as a substrate for precise length and angle standards, and serves as a base for aircraft and submarine navigation.

Core materials for the Ring Laser Gyroscope, Earth Observation and Astrophysics payload, LCD (liquid crystal display), and Used to produce OLED (organic light emitting diode) displays.

Optical mirror substrate material for photo mask imaging on display glass surfaces, extremely small structures in modern integrated circuits on computers and smartphones, enabling the highest precision in chip production.

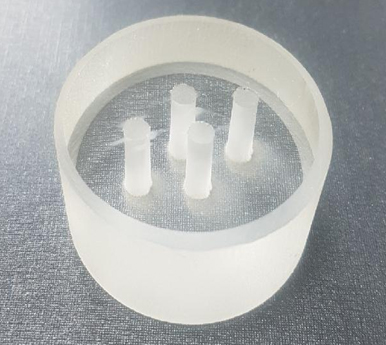

3. Alumina [Al₂O₃]

Alumina is a high-tech refinement that contains more than 80% of alumina, known as alumina ceramics, and is an oxide of aluminum that is used as the main ingredient of ceramics along with silica.

Aluminum oxide is a compound of aluminum and oxygen. High purity alumina, commonly used for pine ceramics, is a fine powder with a purity of over 99.5% and an average particle size of less than 1㎛ , which is relatively well-sourced alumina powder.

Properties of material

- It has characteristics such as stable heat resistance, abrasion resistance, insulation, dielectric, semiconductor, and adsorption even at high temperatures of 1600 degrees.

Major application field

- Electronic components and circuit boards in various high-tech industries, equipment and materials for semiconductor processes, automotive engines, and bio-materials for human skeletons are widely used.

4. Silicon carbide [SiC]

Silicon carbide (SiC) is a compound material that has better thermal conductivity, corrosion resistance, chemical resistance, and low thermal expansion compared to conventional silicon or quartz materials used in LP-CVD processes, so it is less likely to break even in long-term use.

Properties of material

- Chemically safe compounds that do not erode in solutions such as HCI, HF, H2, H2SO4, NaOH, and pure hydrocarbon monocrystals are insulators at room temperature, but their properties vary significantly depending on the type or amount of impurities. When coating a CVD on a SiC surface, the membrane of the surface becomes more dense, preventing the diffusion release of impurity elements, and increasing corrosion resistance for most acidic solutions.

Major application field

- Semiconductor diffusion process and upper pressure CVD, components used in LP-CVD process, cutting tools, mechanical seals, high temperature, spring, engine parts